The main line of the Humen Second Bridge is scheduled to open to traffic in May of next year. PCK supplied the steel pipe for the pile foundation steel casing project

- 2018-12-07 17:15:32

- 1642

On November 20th, the final segmental box girder of the Humen II Bridge was successfully erected, completing the main line

On the morning of November 20th, the last segmental box girder of the Humen II Bridge was successfully erected, completing an important river crossing in the Guangdong, Hong Kong, and Macao Bay Area. The 12.89-kilometer-long mainline is now fully open. The Humen II Bridge is expected to be open to traffic in May 2019, reducing the travel time from Dongguan to Guangzhou Panyu by 30 minutes and effectively easing the traffic pressure on the Humen Bridge. PCK provided steel pipes for the Humen Bridge, which is the largest span bridge in China and the largest span steel box girder suspension bridge in the world.

The bridge spans a total length of 12.89 kilometers, starting from Nansha in Guangzhou, passing through Panyu District of Guangzhou, crossing Humen Port, entering Shatian Town of Dongguan City, and ending at the Guangzhou-Shenzhen-Yanjiang Expressway. The project's main focus is the construction of two cross-river bridges, which will become the world's largest steel box girder suspension bridge upon completion.

The Humen Bridge No.2 is a world-class bridge that connects the east and west sides of the Pearl River in Guangdong, Hong Kong, and Macao Greater Bay Area. Its grand scale and complex construction conditions require solutions for wind resistance, seismic resistance, and fatigue force of steel box girder deck plate. The quality of the corresponding steel pipe helix used for the project must be high, and the process is very difficult.

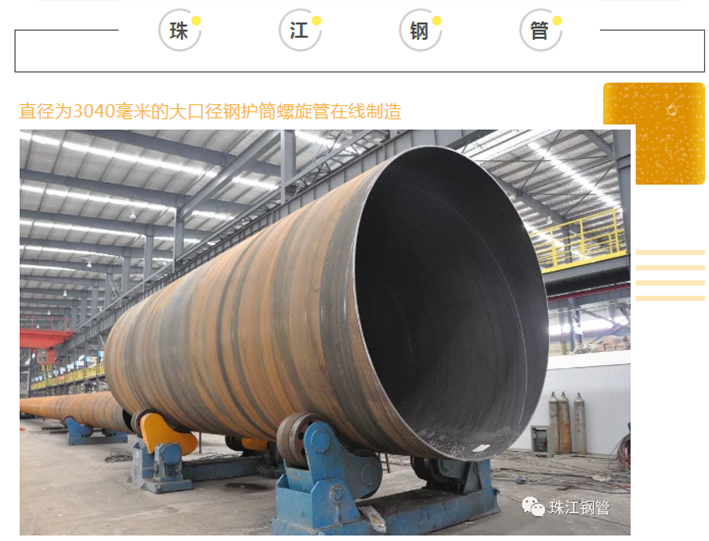

To ensure product quality, PCK Group prioritized the project's production task and requested that PCK Zhuhai put forth their best effort to carefully organize production. The relevant department heads held several thematic meetings to discuss equipment transformation, process optimization, performance testing, and other related topics. Despite facing urgent production tasks, tight deadlines, and other difficulties, the majority of workers were determined, confident, and able to start production work in a relatively short period of time. They successfully completed the task of equipment modification. Through the use of submerged arc welding one-sided bevel butt joints and a one-sided molding process, the unit's design capacity has experienced a breakthrough. The welding standards were strictly implemented to ensure the quality level of the process. Thanks to the joint efforts of everyone, we successfully developed the first batch of large diameter 3040 mm steel pipe spiral. This achievement lays a solid foundation for providing the best quality products for the Humen Second Bridge project.