The first batch of steel pipes manufactured by PCK for the Pearl River Delta Water Resources Allocation Project was successfully delivered

- 2020-09-30 16:08:08

- 2056

September 28th, 2020 is a special and celebratory day. Despite the autumn rain, the employees of PCK remain enthusiastic and dedicated. The PCK Zhuhai team successfully lifted the rumbling machines and steel pipes onto the long board trailer at the shipment site. This marks the beginning of the steel pipe delivery curtain for the Pearl River Delta Water Resources Configuration Project, a key project undertaken by PCK Zhuhai in Guangdong Province. The team is ambitious and ready to move forward.

The Pearl River Delta Water Resources Allocation Project comprises a water transmission trunk line (from Lei Yue Chau water intake to Luotian Reservoir), a Shenzhen sub-trunk line (from Luotian Reservoir to Gongming Reservoir), a Dongguan sub-trunk line (from Luotian Reservoir to Songmushan Reservoir), and the Nansha Branch (from Gaoxinsha Reservoir to the Huangge Water Treatment Plant), with a total length of 113.2km. This project redirects water from the western part of the Pearl River Delta network river area of the Xijiang River water system to the east towards the Pearl River Delta. The main water supply target is the Guangzhou Municipality, and the Guangzhou Municipal Water Treatment Center is responsible for the water supply. The main targets of the water supply are the areas experiencing water shortage in Nansha District of Guangzhou, Shenzhen, and Dongguan. The project implementation can effectively resolve the water shortage issue in the urban economic development of the receiving area. It can also change the current single water supply pattern of Nansha District in Guangzhou City, which draws water from the downstream Shawan waterway of the Beijiang River, and Shenzhen City and Dongguan City, which draw water from the Dongjiang River. This will increase the security of water supply and the capacity of emergency standby guarantee. Additionally, it will appropriately improve the ecological environment flow of the downstream channel of the Dongjiang River during the dry period. Development plays a crucial role.

As the old saying goes, those who want the same thing are more likely to succeed. Considering the project's large pipe diameter (φ4800mm-φ6400mm) and thick walls, as well as the high dimensional accuracy requirements (length deviation ±5mm, ellipticity deviation ≤14.5mm), the pipe takes up a significant amount of space and is difficult to transfer and protect from corrosion. PCK Zhuhai responded quickly and organized production resources in a scientific and reasonable manner. All relevant departments and personnel were fully mobilized, from equipment and facilities to production layout. From the production layout to the process plan, safety, and quality assurance, the entire project team has remained united with high morale, overcoming dimensional problems such as length and ellipticity step by step. The diameter of the ring is welded using automatic submerged arc welding, greatly improving production efficiency. The pouring holes are cut using profiling, significantly enhancing the precision of their size. The company adheres to the principle of maintaining high standards and strict requirements. The company follows the quality control principle of 'high standards, strict requirements, and high quality'. It invests in independent research and development and manufacturing of over ten tooling sets to ensure precise dimensional accuracy and installation of auxiliary accessories. This statement fully reflects that PCK has a profound technical background and superb construction technology. It also embodies the artisan spirit of PCK employees who are not afraid of difficulties and strive for perfection.

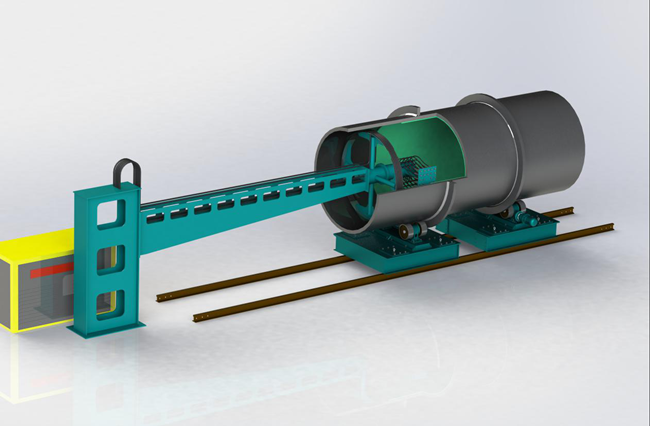

As the saying goes, 'If you want to do a good job, you have to start with good tools.' To ensure compliance with the owner's requirements, the company has constructed the first large-caliber inner wall fusion-bonded epoxy powder spraying anticorrosive production line. Additionally, the outer wall is protected with modified cement mortar to guarantee water supply quality and service life. This is necessary because the project uses φ4800mm-φ6400mm specification large-caliber LSAW pipes.

Currently, conventional FBE anti-corrosion is applied to the outer wall, and this is the first time that the inner wall of a large diameter pipe has been coated in China. However, due to the reinforced ribbed plate structure on the outside of the pipe, it is not possible to heat the medium-frequency coil when passing through the outer wall. PCK Zhuhai conducted technological research and development to utilize a mechanical arm with an integrated front-end spraying device and inner wall heating coil automation system. This system achieves synchronized internal heating and spraying of the pipe body, resulting in smooth and efficient operation of the inner wall. The device is capable of achieving inner wall anticorrosion of steel pipes of varying diameters and lengths, with convenient and quick adjustment. This system fills the gap in domestic large-caliber steel pipe inner wall FBE anticorrosion, enhancing the anticorrosion effect and service life of large-caliber water transmission steel pipes.

We have had a fruitful harvest season, gaining self-confidence and a good start. We will continue to work together, make persistent efforts, climb the peak, and write a wonderful new chapter belonging to PCK's empolyees.