Specification

Outside Diameter:Φ508mm - 2388mm (20“ - 94")

Wall Thickness:6.4 - 25.4mm (1/4“ - 1")

Quality Standards:API, DNV, ISO, DEP, EN, ASTM, DIN, BS, GB, CSA

Length:8.0 - 18.5m (26’ - 62')

Grades:API 5L A-X90, GB/T9711 L190-L625

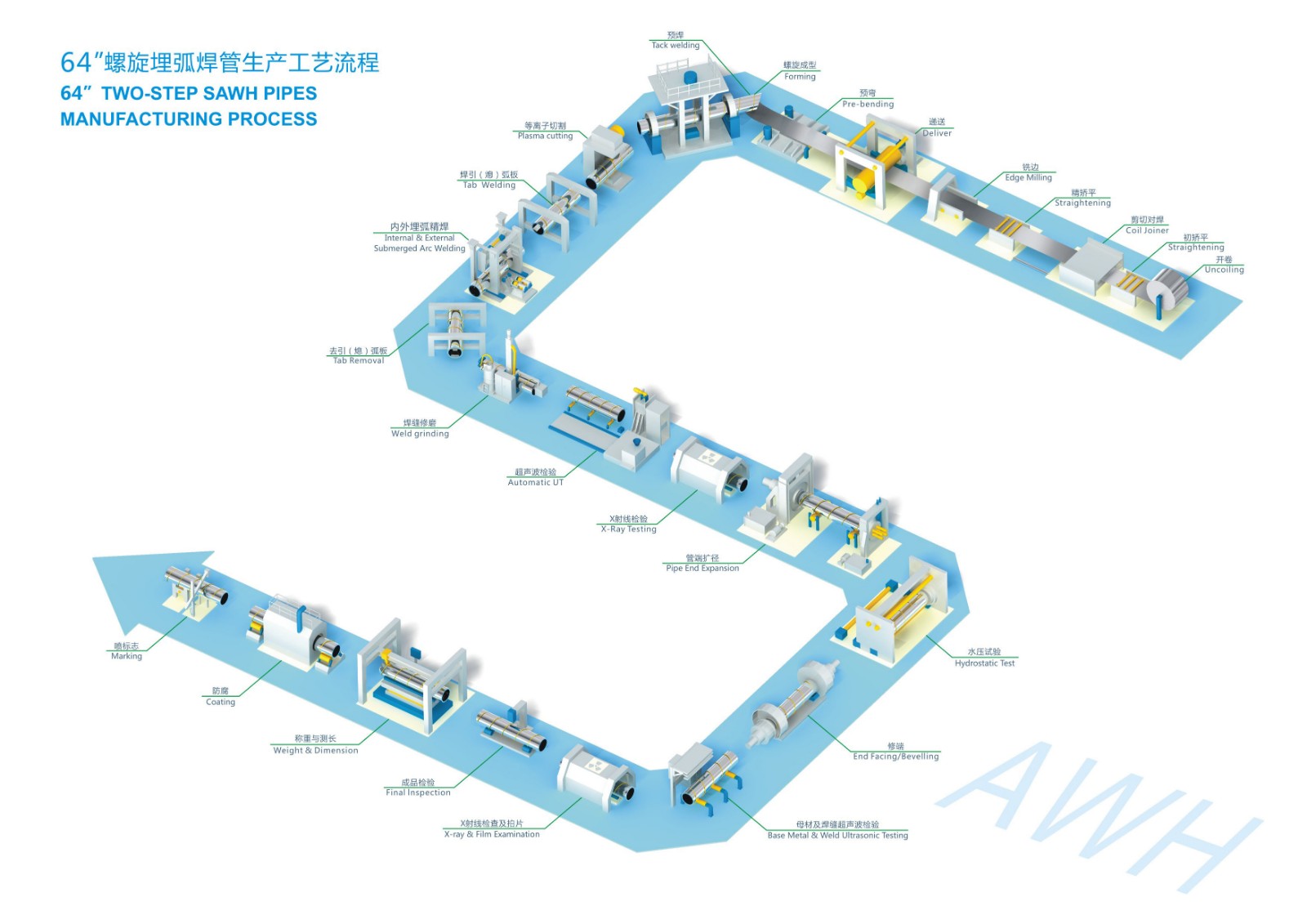

Production Line

This production line utilizes the Two Step Production Process, which is an advanced welding technology. The pipes are first formed into a pipe body and then continuously tack-welded at high speed. In the second step of the process, the pipes are submerged arc welded, resulting in a higher quality weld compared to other SAWH production methods. This process eliminates the tensile stress of the weld seam during pipe forming and submerged arc welding. It also improves the stability of welded joints and productivity. These products are widely used in onshore oil and gas pipelines.